With tailorable configurations ranging from Medical Evacuation to Light Attack / Reconnaissance, the Lakota provides flexibility, scalability, and affordability to U.S. Military operators and to foreign allies and partners.

Delivering on decades of experience, Airbus is a trusted OEM that brings best of breed products and industry solutions to the US Military. Lakota is proudly made at the Airbus helicopter production facility in Columbus, Mississippi by a workforce consisting of more than one-third U.S. military veterans.

The UH-72 Lakota is a highly versatile and reconfigurable aircraft that can be tailored for a range of missions across a variety of conditions and environments. Its missions are as varied as its operating locations, and include training, general utility, search and rescue, reconnaissance, medical evacuation, disaster response, homeland security, counterdrug, command and control and VIP transport.

Made for the Mission

Since 2006, the UH-72 Lakota has served as the US Army’s Light Utility Helicopter performing an evolving range of missions across a range of operational environments. Derived from the highly successful and operationally proven Airbus H145 family of helicopters, which is used worldwide for law enforcement, emergency medical transportation, search and rescue, offshore and utility operations, and corporate transportation, the Lakota has achieved over 1.3 million flight hours.

The Lakota combines operational capability, reliability and affordability, fulfilling all of the military service requirements for speed, range, endurance and overall performance. As a commercial off-the-shelf program, Lakota delivers the advantages of proven production, commercial program improvements, sustained engineering, and capability growth without the normally associated cost burdens of research, development, and testing.

Incorporation of proven and new COTS technologies, combined with the UH-72's operational capabilities, result in an aircraft that is exceptionally simple and affordable to operate and maintain. Extensive use of new, lightweight manufacturing materials and system modularity simplifies maintenance, reducing lifetime ownership costs and logistics requirements.

UH-72A

U.S. Army pilots benefit from the UH-72A’s VEMD (Vehicle and Engine Multifunction Display) and its night vision goggle (NVG) compatible glass cockpit, which synthesizes flight and vehicle information, increasing situational awareness and reducing crew workload.

The Lakota's redundant hydraulic, electrical, and engine control systems – combined with its crashworthy airframe and energy-attenuating pilot and passenger seats – add a high level of flight safety and survivability to the type’s exceptional flight characteristics. Power from the aircraft’s reliable Arriel turboshafts is delivered through a proven hingeless rotor system to the UH-72A’s advanced technology composite rotor blades. Coupled with advanced blade design, this decreases vibration and noise, while enhancing aerodynamic efficiency and mission performance.

The UH-72A's unobstructed main cabin is easily re-configurable to maximize mission flexibility. The helicopter's sliding side and rear clamshell doors optimize access and effective space utilization, offering rapid troop deployment and substantial mission growth potential. The Lakota can carry up to nine troops and two stretchers can be installed for MEDEVAC missions.

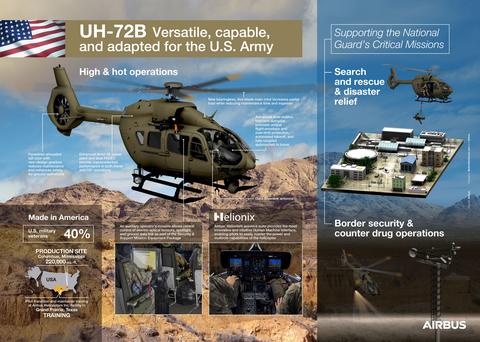

UH-72B

In September 2021, the latest variant of the Lakota family of aircraft – the UH-72B – was delivered to the U.S. Army.

The UH-72B delivers numerous product improvements developed during the lifecycle of the commercial aircraft, including improved power, controls, avionics and safety enhancing features. Aircraft improvements were developed and incorporated at no additional cost to the government.

The Fenestron shrouded tail rotor comes with a newly designed gearbox that reduces maintenance and enhances safety for ground operations and a new bearingless, five-bladed rotor increases the aircraft’s load capacity while reducing expense and maintenance.

An enhanced Arriel 2E power plant and dual full authority digital engine control (FADEC) gives the aircraft more power, and a four-axis autopilot strengthens controls and allows for automated takeoffs. An auxiliary operator’s console offers central control of electro-optical sensors, spotlight and ground data link as part of the security and support mission equipment package.

Pilots benefit from the advanced Airbus Helionix avionics suite, which provides the most innovative and intuitive human-machine interface and improved situational awareness on the market today. The advancement to four-axis autopilot strengthens controls, reduces pilot workload, allows for automated takeoffs, and brings improved inflight and hover automated controllability.

Infographic

UH-72B-Infographic

Jpg 1.45 MB

Featured UH-72

Related news

U.S. Army awards Airbus contract for Continued Logistics Support

U.S. Army National Guard to operate first UH-72B in Arizona

Explore more